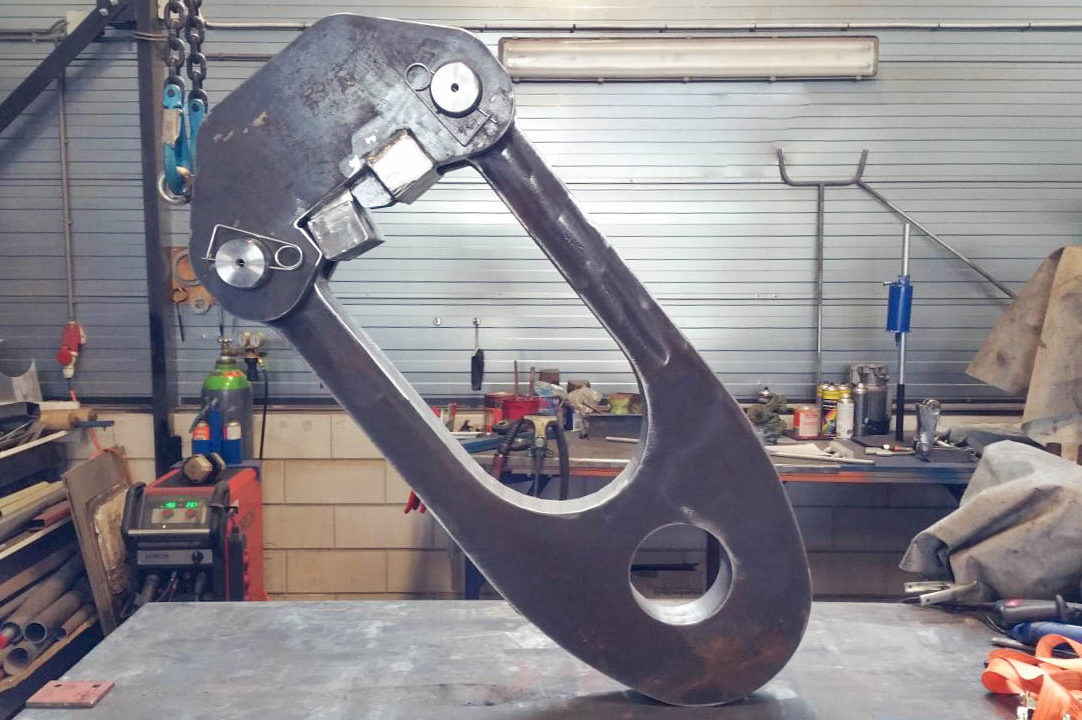

WLL 1 TON HOOKBLOCK

Developed for the lifting operations performed by a Walk-to-Work system. The capacity of this hook block is 1 metric ton.

In this hook block the clump weight, swiveling hook and hoist wire attachment are an integral design providing minimal hook block length and maximum protection for the wire socket.

WLL 5,5 TON HOOKBLOCK

The construction of this hook block is very similar to the 1 ton block. The main difference is the possibility of varying the clump weight mass , in this case between 180 kg and 280 kg, without changing the lifting capacity. This way, the hook block can be tailored to a wide range of cranes.

SOCKET TESTING YOKE

The socket testing yoke was developed to test sling sockets in a hydraulic test frame. The design can be scaled to fit various capacities. The existing design has a capacity of 200 tons.

SELF-ALIGNING DOCKING CONNECTOR

The self-aligning docking connector was developed specifically for operations where it is difficult for the crew to guide and attach a crane hook to the payload. The connector is fixed to the crane hook through a spelter socket and connects to the hub rotating through a C-shaped receptacle.