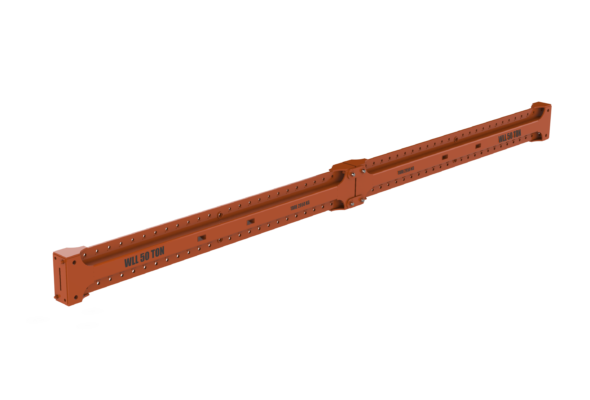

MULTI-TRUNNION LIFTING BEAMS

A trunnion represents an attachment point for the rigging (slings/grommets) on each side of the lifting beam. Thus, multi-trunnion lifting beams allow rigging attachment to the lifting beam at various widths.

The use of trunnions makes rigging procedure quicker and easier by eliminating the use of multiple shackles in the attachment of slings, but also by the built-in possibility of easily modifying the spread of the slings.

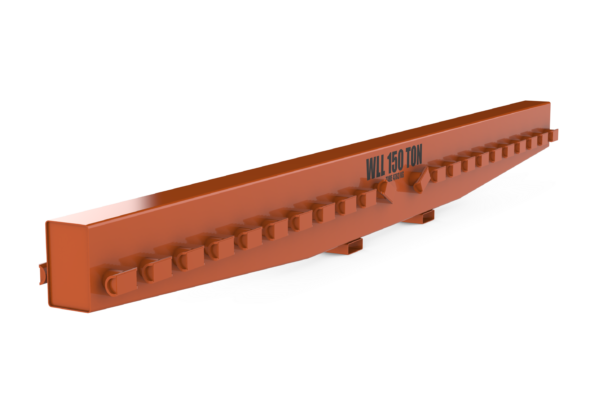

MULTI-LUG LIFTING BEAMS

Multi-lug lifting beams can be used when multiple lifting points are required. They also allow a quick change in rigging layout without the need for changing or modifying the lifting gear.

Needless to say, this type of lifting beam are suitable for lifting operations where multiple items with varying centers of mass and lift point layouts need to be handled.

SPREADERS

TILLEN has been designing and managing all fabrication and certifying processes for various types of spreaders.

When a specific lifting challenge arises, we can assess the circumstances in which the lifting is to be performed and design the optimal solution for a safe lifting arrangement.

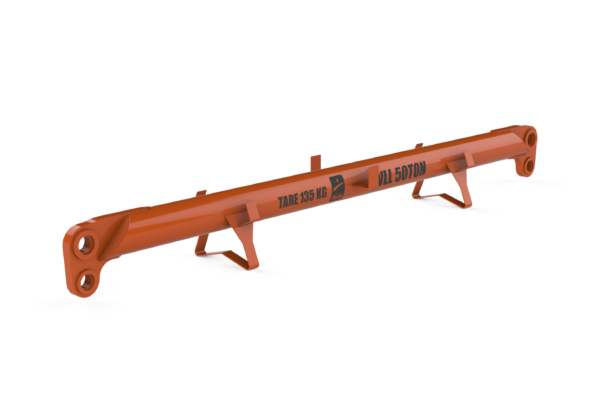

LIFTING YOKE

Lifting yokes feature a single lifting point and can be used to directly attach the load to the lifting hook, eliminating the compressive forces from the slings that would occur in a lifting operation or in a spreader beam with top rigging.

This type of lifting gear is application-based and TILLEN can assess the lifting operation and determine which type of lifting gear is most suitable, for instance when a swiveling yoke is required we can adapt the design accordingly.

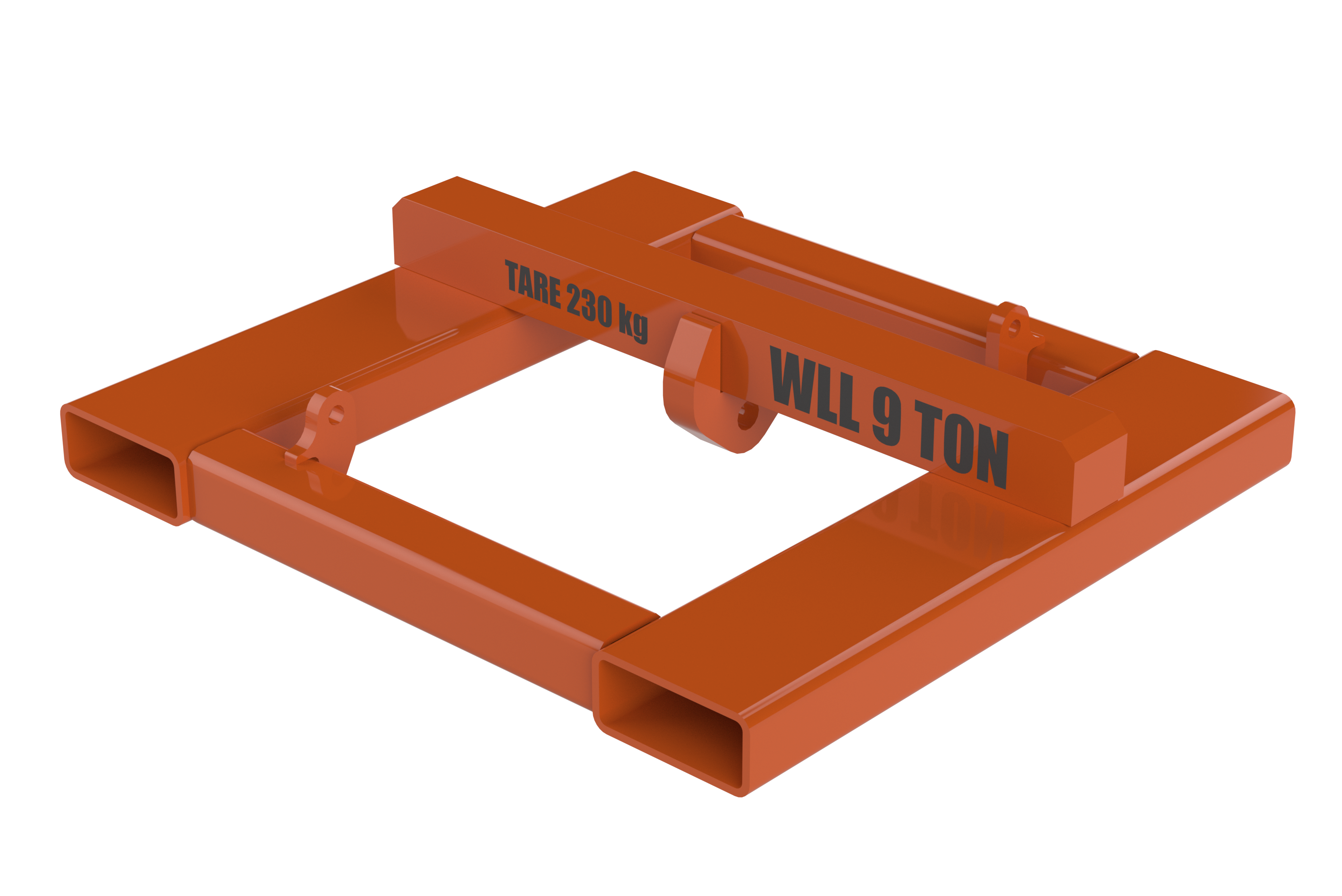

FORKLIFT LUG

For applications in which forklifting operations are required, we can supply a forklift lug that is instantly usable, provides safe and stable lifting and eliminates the need for on-the-spot solutions.